[Q] Customers often come to consult plastic welding methods, and what are the characteristics of various plastic welding methods?

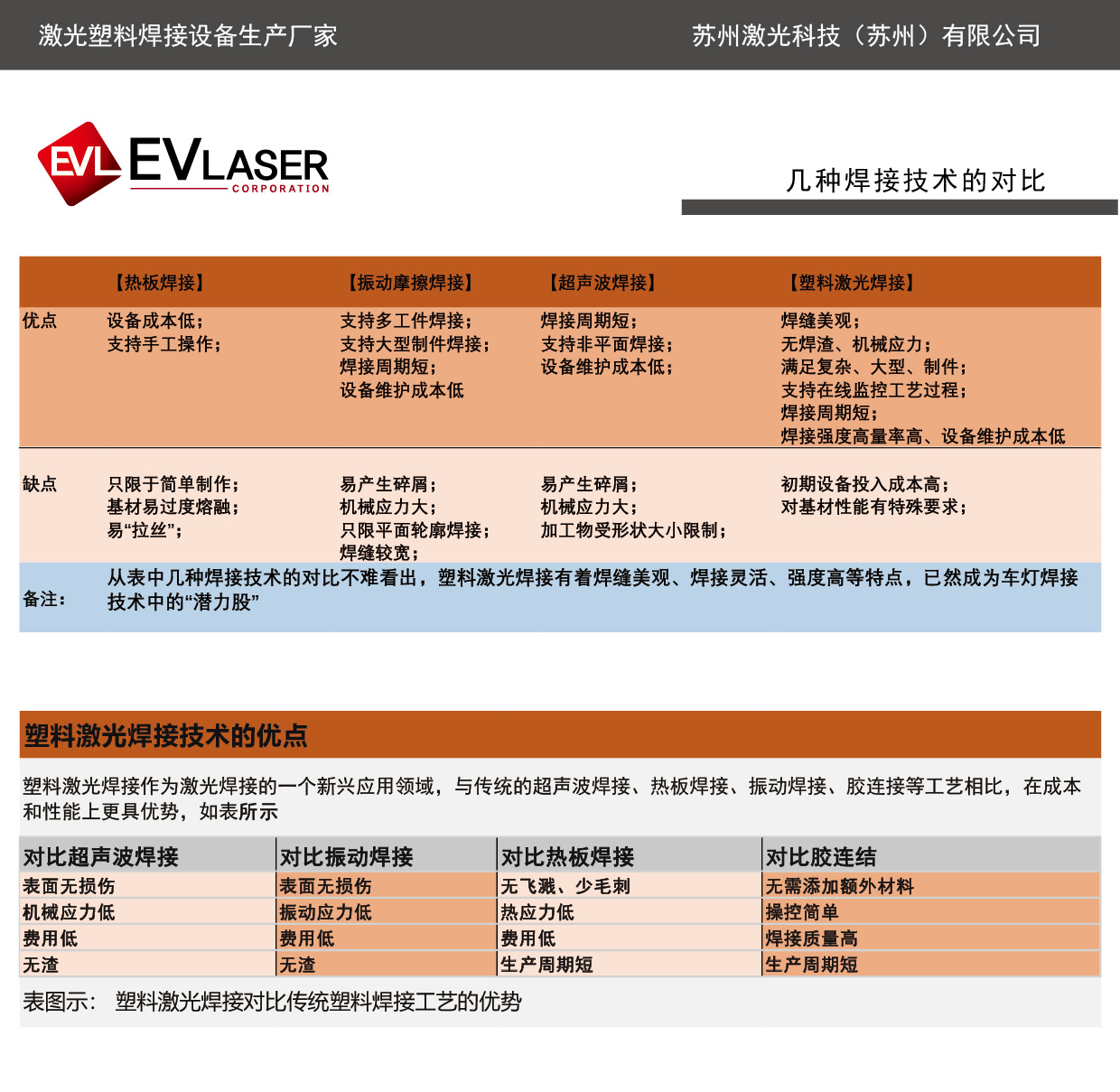

Plastic welding is roughly divided into two kinds of traditional plastic welding process and laser plastic welding process:

Traditional plastic welding process:

one Hot plate welding may be the simpler plastic welding technique, but this method is particularly suitable for large area welding. For the welding of plastic parts with large surfaces, it is generally a flat electric heating plate that melts and softens the two planes to be welded, and then quickly removes the electric heating plate to combine the two planes and apply force to cool them. The welding device is simple, the welding strength is high, and the shape design of products and welding parts is relatively easy. However, due to the heat generated by the hot plate, the product softens and the cycle is long; The melted resin will adhere to the hot plate and is not easy to clean (applying F4 on the surface of the hot plate can reduce this phenomenon), and the formation of impurities over time will affect the bonding strength. To strictly control the pressure and time to ensure the proper melting amount; When different kinds of resins or metals are bonded with resins, insufficient strength will occur.

2. Hot air welding When the hot air flows directly to the joint area, the filler wire of the same material as the base material in the joint area will melt. The weld is formed by melting the filler material and the plastic that is welded together. The welding equipment of this welding method is light in weight and easy to carry, but it requires higher welding skills of the operator.

3, hot rod welding and pulse welding two technologies are mainly used for the welding of plastic films with small thickness. The two methods are similar in that they both press two films together and use the instantaneous heat generated by a hot rod or nickel-chromium wire to complete the welding. Welding technology of mechanical motion softening: friction welding, ultrasonic welding;

4, friction welding: according to the movement path can be divided into linear and rotary; Straight line can be used for straight line welding and plane welding. The rotary type can be used for the welding of circular welds. The friction heat generated by the pressure of the two parts during the friction process causes the plastic in the contact part to melt, soften, and align until it solidifies. However, friction welding may cause damage to the internal components. Friction welding (rubbing) through friction, flatness, appearance may have an impact.

5, ultrasonic welding: the use of high-frequency mechanical energy to soften or melt the thermoplastic at the joint. The connected parts are held together under pressure and then subjected to ultrasonic vibration, usually at a frequency of 20 or 40 kHz. The transducer converts the high-power vibration signal into the corresponding mechanical energy, which is applied to the plastic parts to be welded. When contacting the interface, the intense friction at the joint of the weldment instantly generates high heat, which makes the molecules alternately fuse, thus achieving the welding effect. However, in the daily operation of ultrasonic welding (low-cost) most will be used, ultrasonic welding, the noise is particularly large, through friction welding, there may be damage to the precision devices inside the product.

6, infrared welding: the technology is similar to the welding of electric heating plate, the two parts that need to be welded are fixed near the electric heating plate but not in contact with the electric heating plate. Under the action of thermal radiation, the connection part is melted, and then the heat source is removed, and the two parts are butted and pressed together to complete the welding. The method has no welding slag, no pollution and high welding strength. It is mainly used for the connection of PVDF, PP and other pipeline systems with high precision requirements.

Laser plastic welding process:

1, laser plastic welding: in the 1970s, laser began to be used in plastic welding. The principle is to focus the beam generated by the laser (usually the strong radiation wave in the infrared region of the electromagnetic spectrum) through the optical path system composed of a mirror, lens or fiber, and focus on the area to be welded. Form a thermal effect zone. Plastics in plastics soften and melt. In the subsequent solidification process, the melted material forms a joint, which is connected to the parts to be welded, usually used for PMMA, PC, ABS, LDPE, HDPE, PVC, PA6, PS, etc. For materials with good light transmittance. Plastic laser welding has many advantages: fast welding speed, high precision; Automation and precision CNC are easy to implement; The cost is relatively low. Therefore, plastic laser welding technology has been widely used in automotive, medical equipment, packaging and other fields.

As a manufacturer of laser plastic welding equipment in Suzhou, the production of plastic laser welding equipment is mainly used in automotive rear taillights, car cameras, automotive tire pressure monitoring meters, medical fluid devices, microfluidic devices, liquid cooled lamps and other products in the field of plastic laser welding work, Suzhou EVLaser plastic welding equipment is mainly sold to: Guangdong, Hebei, Shanghai, Guangdong, Jilin, Hubei, Chongqing, Beijing, Zhejiang, Liaoning, Jiangsu, Tianjin, Sichuan, Henan, Hunan, Suzhou, Ningbo, Changzhou, Yancheng, Jiaxing, Nantong and other provinces and cities. Manufacturer's price, welcome to call: 0512-65158026