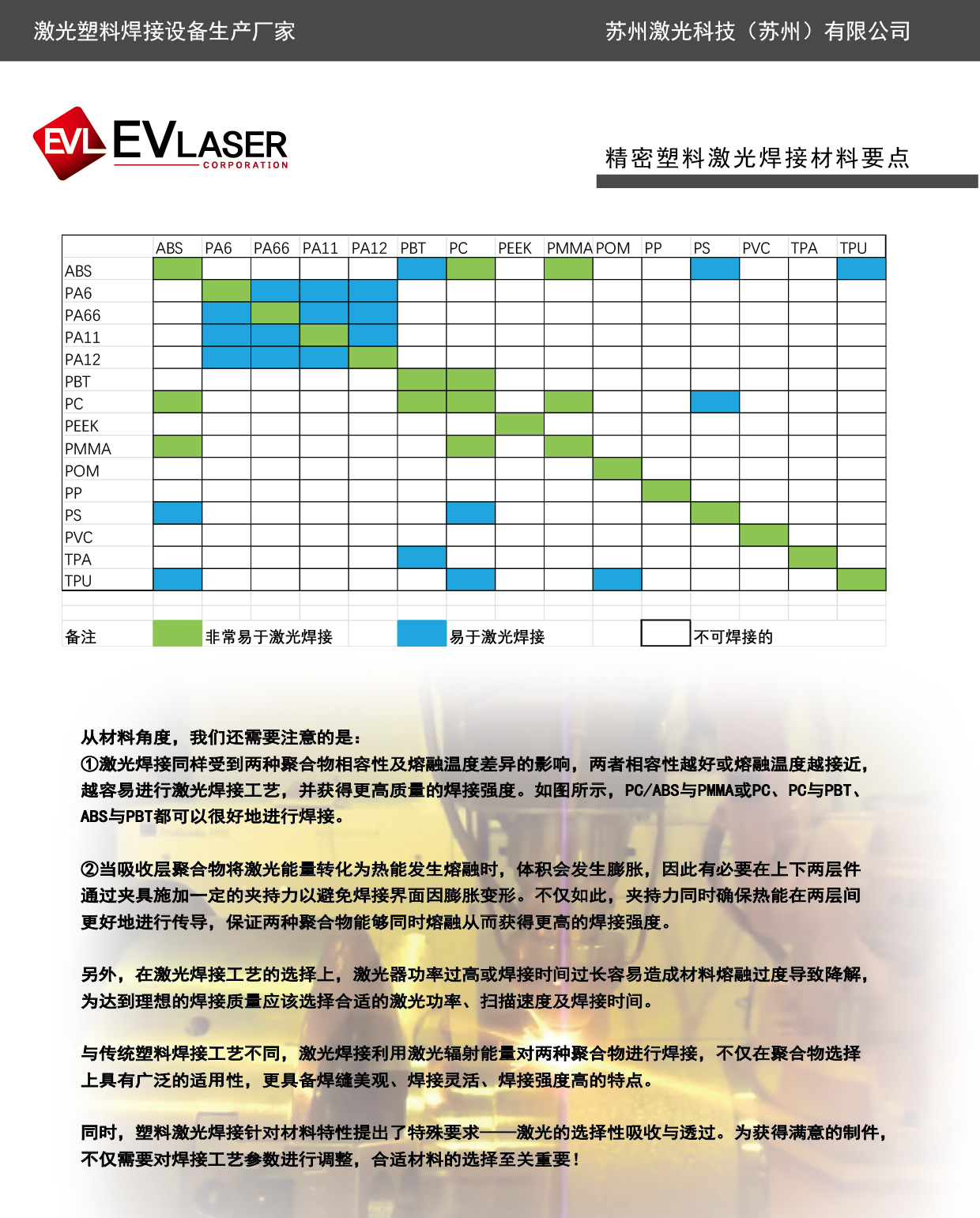

[Q] Can PP material and PC material be welded with plastic laser welding technology? As to whether PP (polypropylene) and PC (polycarbonate) plastics can be welded together by laser welding technology, there are certain challenges, but not completely impossible. First of all, PP and PC have differences in physical and chemical properties, such as melting point, light transmittance, etc., which may affect their compatibility in the laser welding process. However, modern laser welding technology has developed a variety of ways to deal with the welding difficulties between different plastics. One possible approach is to employ laser-assisted welding techniques, such as infrared heat-assisted or laser transmission welding. With the aid of infrared heating, the weld area can be preheated by an external heat source to improve the melting point and fluidity of the material, thereby increasing the success rate of welding. For laser transmission welding, if the PC plastic is transparent, and the PP plastic is not transparent, then the PC side can be coated with absorbent to enhance the absorption of laser energy, and then achieve welding. However, it should be noted that even with these methods, laser welding of PP and PC plastics may face some challenges, such as weld strength, heat affected zone control, welding speed, etc. All these need to be solved by optimizing process parameters and selecting suitable auxiliary materials in practical applications. In addition, it is also necessary to consider the use requirements of PP and PC plastics in different application scenarios. For example, in the fields of medical devices, automotive manufacturing, etc., there are high requirements for the strength and tightness of welded joints, so it is necessary to choose a more refined and reliable welding process. Therefore, although there is a certain difficulty in welding PP and PC plastics, they can be welded together through modern plastic laser welding technology and appropriate process optimization. However, in practical applications, appropriate welding methods and process parameters need to be selected according to the specific situation to ensure welding quality and efficiency.