What is laser plastic welding?

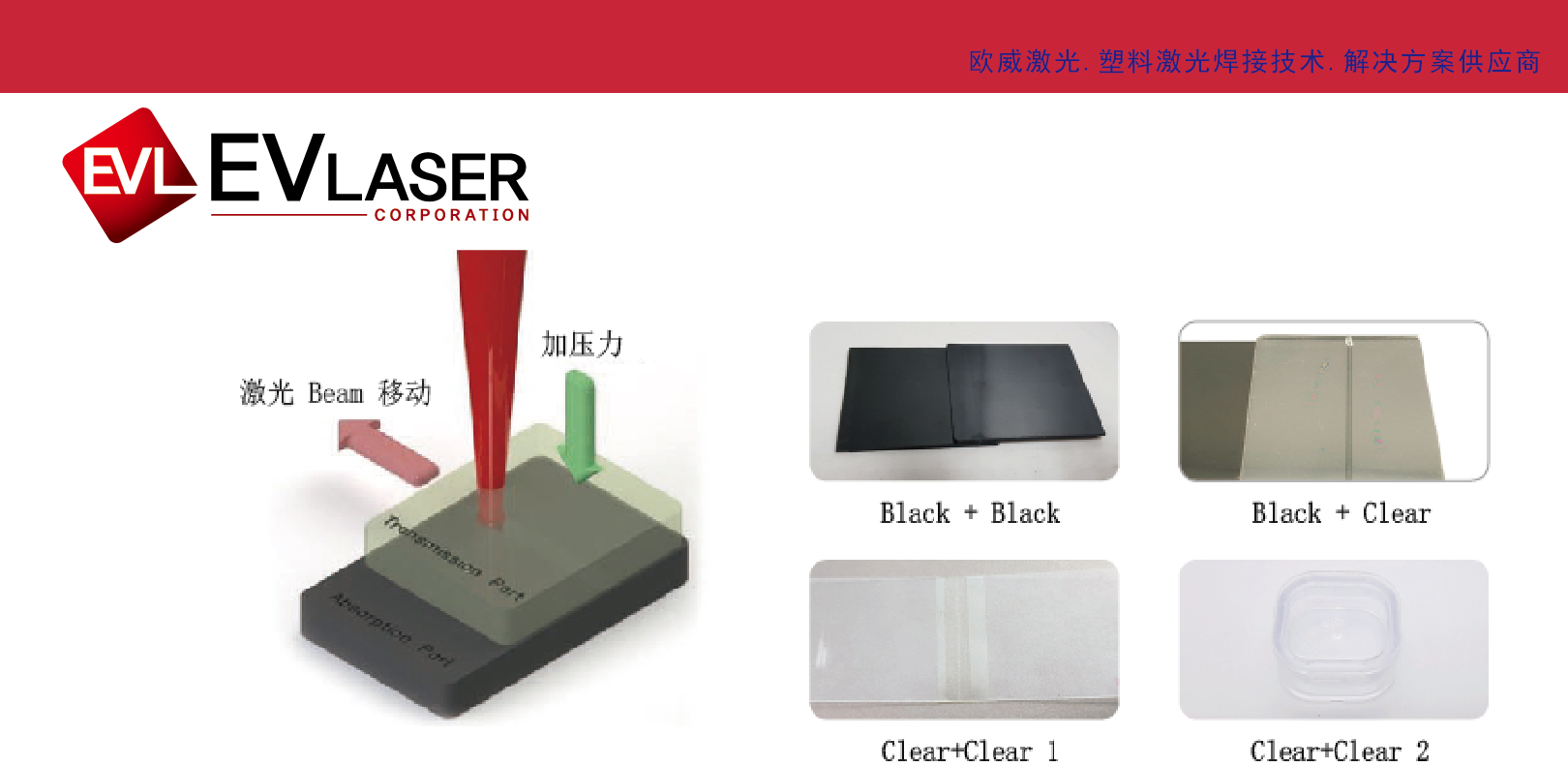

Technology introduction: The upper base material of the transmitted laser beam and the lower base material that absorbs the laser beam are stacked up and down, and then the laser is irradiated on the upper material that can pass through the laser, the laser reaches the interface of the lower base material to increase the surface temperature of the lower base material, and the heat generated in the process is transferred to the upper layer, so that the two base materials melt and combine.

Chinese name: Laser plastic welding

Name: Laser Plastic Welding

The main parameters of laser plastic welding:

· Wavelength and characteristics of the laser beam

· Laser output · Optical characteristics

· Transmittance and absorptivity of the material

· Material thickness and color

· Transfer device, pressure device and quality control device

The main application areas of laser plastic welding:

· Parts requiring high water tightness and pressure resistance

· Products in the industrial field that value appearance quality

· Automotive, electrical/electronic parts

· Transparent material products for the medical industry

· Plastic parts welding in precision electronics consumer field

· Plastic parts welding for industrial packaging